Hot melt adhesives are unique because of it’s application temperature and is capable of simplifying production processes. It’s ideal to implement in streamlined manufacturing It fast speed of set, high bond strength, low application costs and processing safety are at the foundation of its worldwide success. Manufacturing processes in various industries like electronics, medical, automotive, furniture or food and beverage rely on this adhesive technique.

What are Hot Melt Adhesives?

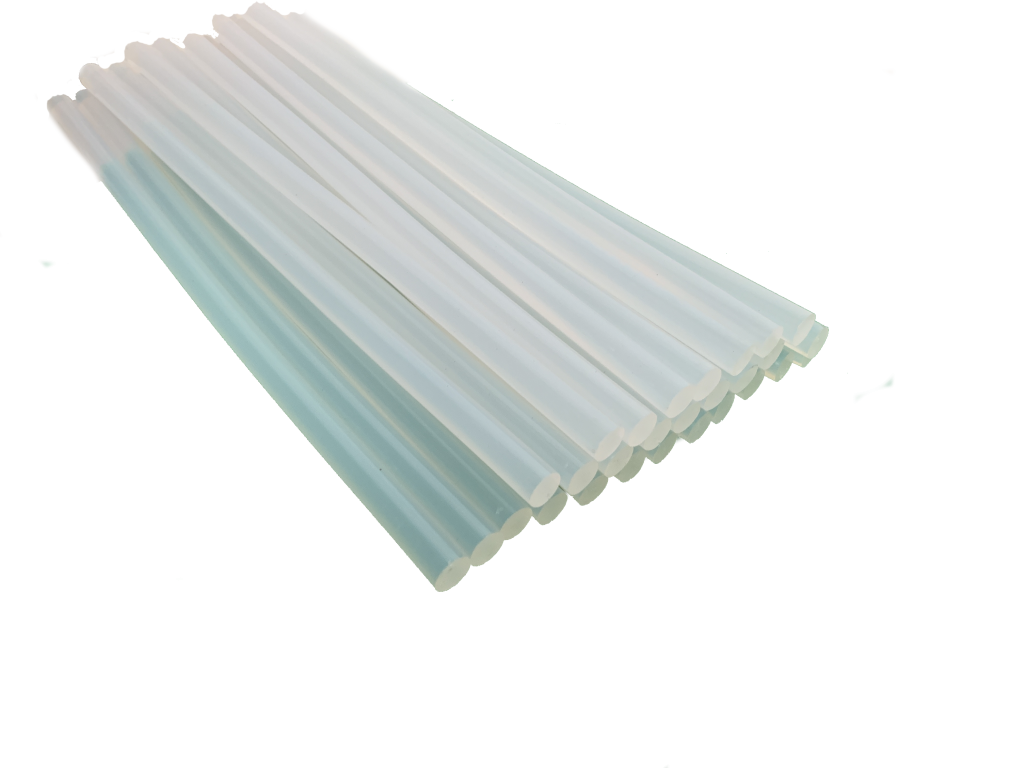

Hot melt adhesives are meltable solid materials, like a plastic. It starts to melt at approximately 80°C and is often applied at 160°C. In the fluid stage it already has some hot tack, the unique fast setting is realised by it’s quick cooling down after hot application.

Available basic materials for Hot Melt Adhesive Materials

- Copolymers of ethylene vinyl acetate (EVA)-based hot melt adhesives

- Amorphous poly-α-olefin-based hot melt adhesives

- Polyolefin-based hot melt adhesives

- Synthetic rubber-based, PSA, hot melt adhesives

- Polyurethane-based, PUR, hot melt adhesives

How Hot melt adhesives are applied

Hot melts require high temperatures to be applicated, mostly 160°C. Common used hot melt equipment is Nordson, but many others offer specific equipment to apply hot melt adhesives in industrial applications.

Usage of Hot Melt Adhesives

Hot melt adhesives do optimize manufacturing processes in many markets and applications.

- Hot melt adhesive for sealing

- Food packaging

- Label industry

- Paper manufacturing

- Furniture industry

- Self adhesive tapes

- Automobile industry

- Self adhesive labels

- Book binding industry

- Product assembly

- Clothing special materials industry

- White goods assemlby

- The electronics industry

- Shop display manufacturing

- Gift box assembly industry

- Disposable hygiene products industry

- Filterindustrie

- Footwear