Pressure-sensitive adhesives are physically setting systems that are characterised by their permanent tack. The adhesives achieve their adhesion to the materials to be bonded by means of a contact pressure to be exerted – with increasing contact pressure a better adhesion is produced. As the joining of pressure-sensitive adhesives can take place both before and after the setting process, depending on the strength of the permanent tack, they are often used for pre-coating. This means that the application process can be carried out independently of the bonding in terms of time and space.

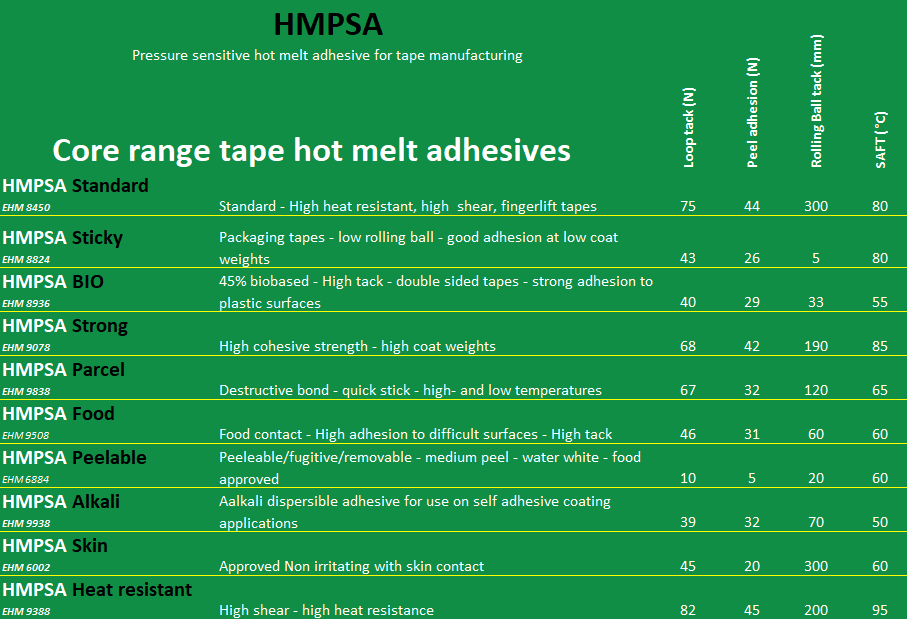

Hotmelt pressure-sensitive adhesives from Intercol are characterized by high adhesion to different materials, and by high strength and flexibility. In processing, these modern adhesives score points due to their above-average initial tack and outstanding viscosity stability.

Tacky

Pressure-sensitive adhesives are characterised by their permanent tack. With only contact pressure there is a quick adhesion is produced, the more pressure applied, the higher the adhesion strength is. As the joining of substrates with pressure-sensitive adhesives can take place both before and after the hot setting process, it can be used with inline applications but are more often used for pre-coating.

Hotmelt pressure-sensitive adhesives can often provide high initial tack to different materials and high strength and flexibility.

Properties

Hotmelt pressure sensitive adhesives offer the following advantages:

- High inline production speeds, no intermittent stops.

- Solvent free, 100 % solids contents

- Broad adhesion spectrum to different materials

- Filling properties, levelling of the surface

- Elasticity of the glue line

- Pre-coating possible for tapes and self adhesive labels

- Adhesive joint can be released by heat input.

- Alkali dispersable grades are available for plastic recycling.

Parcel boxes

Parcel boxes, envelopes and other packaging materials are often produced with self-adhesive closures.

.