Hot-melt adhesives are solvent-free or water-free products that are more or less solid at room temperature, are present in the hot state as a viscous liquid and are applied to the adhesive surface. On cooling, they solidify reversibly and form a firm bond. This group of adhesives are thermoplastic polymers based on different chemical raw materials

What is a hot melt adhesive?

Thermoplastic and curing hot melt adhesives

Hotmelt adhesives can be divided into physically and chemically setting adhesives. The physically setting adhesives are thermoplastics, the chemically setting ones form thermosets, i.e. three-dimensional networks. Another type of classification is regarding the solidification mechanism. Here, hotmelt adhesives are divided into amorphous polymers, semi-crystalline polymers, and high-molecular polymers, the first two having a glass transition temperature above room temperature and the latter having a glass transition temperature below room temperature

EVA and polyolefin

The main polymers used for physically setting hot melt adhesives are polyamide resins, saturated polyesters, ethylene-vinyl acetate (EVA) copolymers, polyolefins, block copolymers (styrene-butadiene-styrene or styrene-isoprene-styrene) and polyamides.

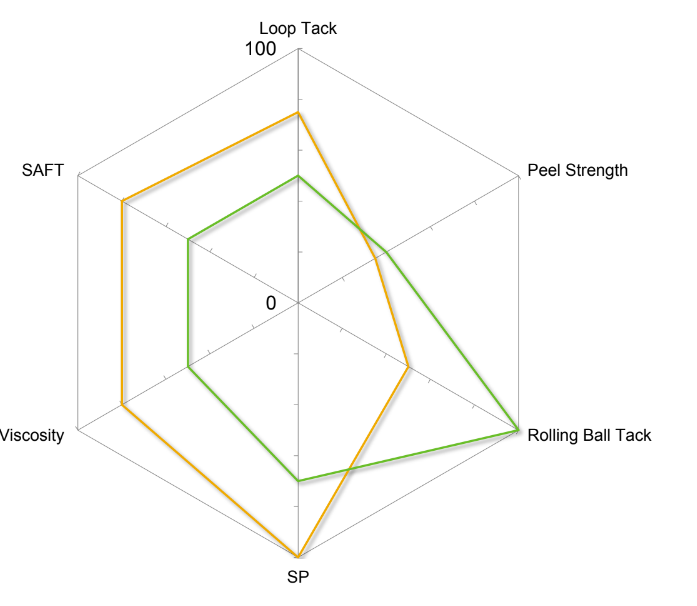

PSA

Pressure-sensitive adhesives are physically setting systems that are characterised by their permanent tack. The adhesives achieve their adhesion to the materials to be bonded by means of a contact pressure to be exerted – with increasing contact pressure a better adhesion is produced. As the joining of pressure-sensitive adhesives can take place both before and after the setting process, depending on the strength of the permanent tack, they are often used for pre-coating. This means that the application process can be carried out independently of the bonding in terms of time and space.

Hotmelt pressure-sensitive adhesives from Intercol are characterized by high adhesion to different materials, and by high strength and flexibility. In processing, these modern adhesives score points due to their above-average initial tack and outstanding viscosity stability.